PRODUCT CENTER

OUR COMPANY ADOPTS ADVANCED DESIGN CONCEPTS, EQUIPPED WITH ADVANCED NUMERICAL CONTROL PROCESSING, TECHNOLOGY

AND TESTING EQUIPMENT TO ENSURE THE QUALITY AND PERFORMANCE OF VIBRATING SCREEN MANUFACTURING.

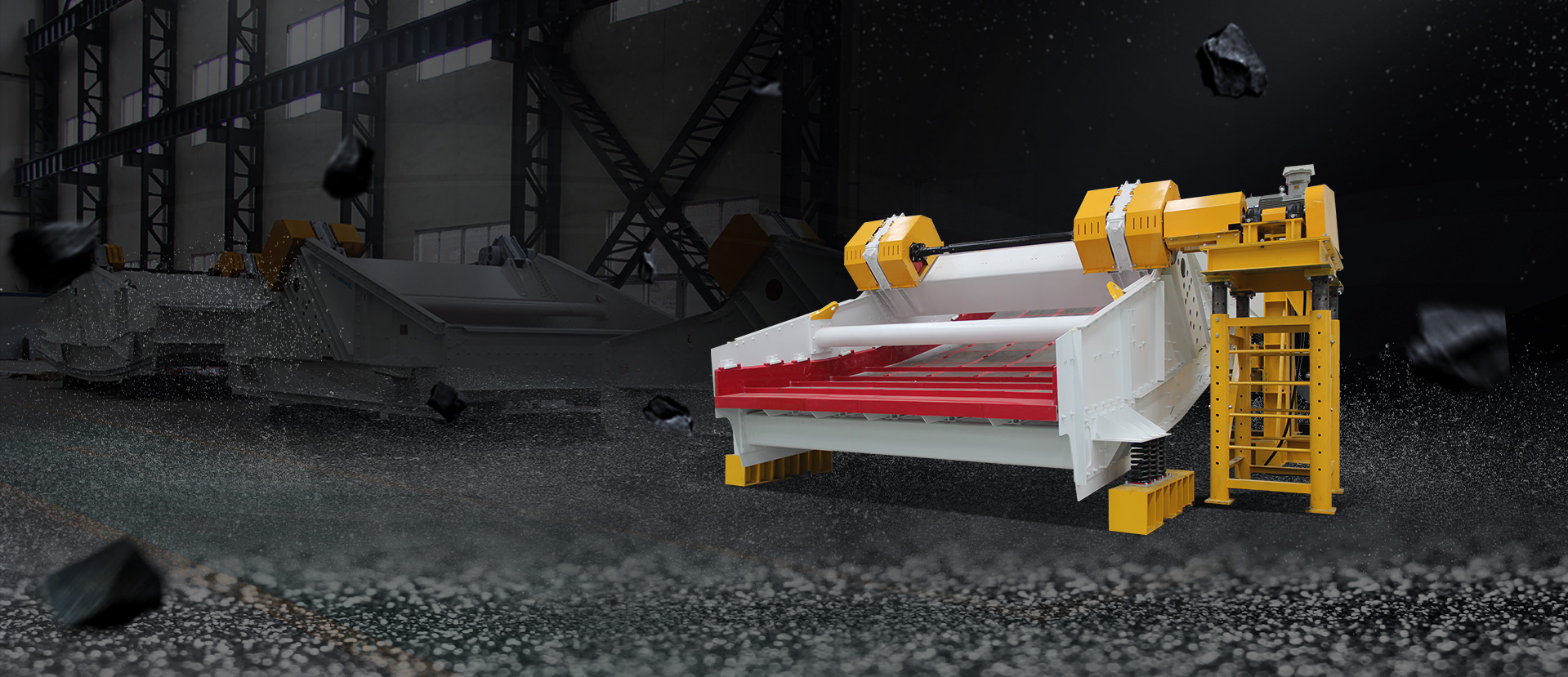

Vibrating Screen

Haiside vibrating screen adopts advanced design concepts and is equipped with advanced numerical control processing technology and testing equipment to ensure the quality and performance of the product and the safety of the vibrating screen.

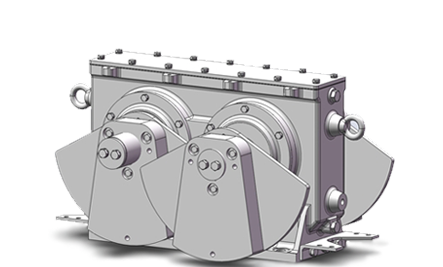

Vibrating Screen Exciter

The vibrating screen exciter is mainly used to realize the conveying, screening, compacting, forming, and tamping of soil sand and gravel of materials or objects. Mainly divided into HE (FE) NE, DF, ZDQ, RDQ, JR, KWD, DVE and other product series.

Coal Centrifuge

Haiside Coal Centrifuge adopts advanced design required by the coal industry. The main components are selected from internationally renowned brands, and the equipment has a long service life. At the same time, we provide professional technical support.

Benefits of Using a High-Frequency Vibrating Screen Exciter in Industrial Screening

/in News /by adminIn industries such as mining, quarrying, construction materials, and chemical processing, efficient material screening is a critical step that directly affects product quality, production capacity, and operating costs. As material specifications become more demanding—especially for fine and ultra-fine particles—traditional low-frequency screening methods often struggle to deliver stable and accurate results. This is where a high-frequency […]

How Exciter Power Affects Screening Efficiency: Insights from a Vibrating Screen Manufacturer

/in News /by adminIn mining, quarrying, and aggregate processing, screening efficiency directly impacts production output and operating costs. While many operators focus on screen size or mesh selection, exciter power is often underestimated. From a vibrating screen manufacturer’s perspective, exciter power determines how effectively vibration energy is transferred to the material. When properly matched, it improves separation accuracy, […]

The Critical Role of an Exciter in Mining Vibrating Screens: Ensuring Efficiency and Precision

/in News /by adminIn modern mining operations, efficiency and precision are key to profitability. Among the many pieces of equipment that make this possible, the vibrating screen is indispensable. While the screen deck and motor often receive the most attention, the exciter is the true engine driving the screening process. Understanding its role can help mining operators optimize […]

Custom Vibrating Screen Exciter Price and Quotation: What You Need to Know

/in News /by adminAs industries such as mining, sand and gravel, chemicals, and metallurgy continuously increase their demands for screening efficiency and product quality, the importance of vibrating screen exciters is becoming increasingly prominent. As the core power source of the vibrating screen, it determines the amplitude, frequency, stability, and screening capacity of the entire machine. For companies […]