What are the types of vibrating screen exciters?

Vibrating screen exciters are mechanical devices that generate the vibration necessary for screening materials in industries such as mining, metallurgy, and construction. There are several types of vibrating screen exciters, each with its unique design and method of operation.

Vibrating Screen Exciters Types

1. Electromagnetic Exciters:

Operation: Electromagnetic exciters use an electromagnetic field to create a vibrating motion. The alternating current passed through a coil creates a magnetic field that moves the screen.

Usage: These are often used for fine material screening, where high-frequency vibrations are required.

2. Unbalanced Motor (or Rotary) Exciters:

Operation: These consist of a motor with unbalanced weights attached to either end of the rotor shaft. As the motor spins, the unbalanced weights generate centrifugal forces, causing the screen to vibrate.

Usage: Common in both circular and linear motion screens, these exciters are versatile and used in many screening applications.

3. Gearbox Exciters:

Operation: These exciters use a gearbox that drives the screen’s vibratory motion. The gearbox typically contains gears that generate a consistent vibratory motion when powered by an electric motor.

Usage: Often used in heavy-duty applications where significant vibration forces are needed, such as in mining screens.

4. Direct Drive Exciters:

Operation: In direct drive exciters, the vibration is generated directly by an electric motor without any intermediate gearbox or mechanical linkage. The motor is typically mounted directly on the screen.

Usage: Used in high-frequency and fine material screening, they provide precise control over the vibration frequency.

5. Hydraulic Exciters:

Operation: Hydraulic exciters use hydraulic fluid to drive a piston or actuator, which creates the vibratory motion. The system can be precisely controlled to vary the frequency and amplitude of the vibration.

Usage: Common in applications requiring variable control over vibration and often used in heavy-duty or specialized screening operations.

6. Eccentric Shaft Exciters:

Operation: Eccentric shaft exciters consist of a rotating shaft with an offset mass (eccentric weight) that generates a circular motion as the shaft rotates.

Usage: Widely used in circular motion screens, they are reliable and effective in handling large materials.

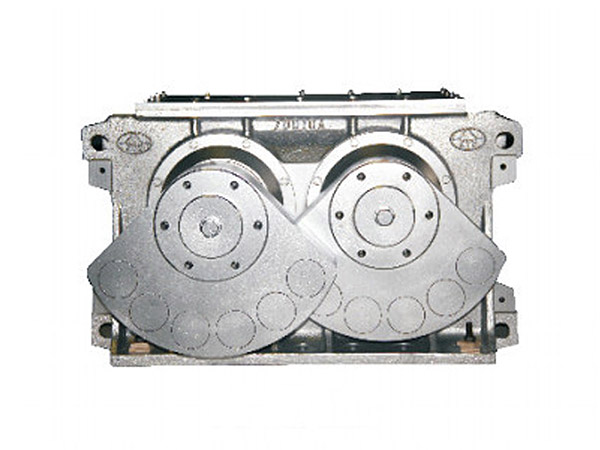

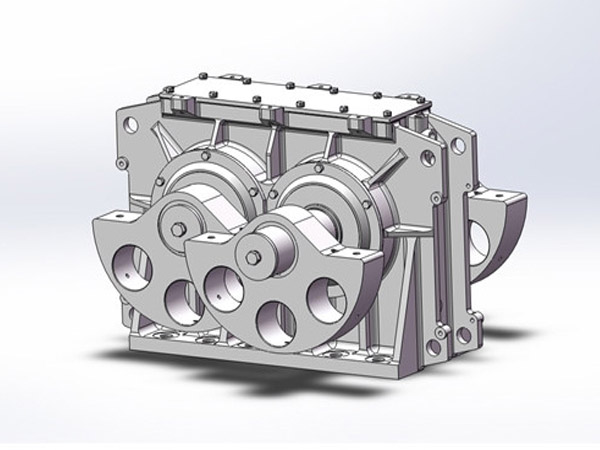

7. Twin-Shaft Exciters:

Operation: Twin-shaft exciters use two shafts synchronized with gears. These shafts rotate in opposite directions, generating a linear motion in the vibrating screen.

Usage: Ideal for linear motion screens, often found in heavy-duty applications such as mining and aggregates processing.

Each type of exciter is suited to specific applications depending on the material being processed, the desired screening efficiency, and the operational requirements.