Precautions for installation, commissioning and maintenance of linear vibrating screen

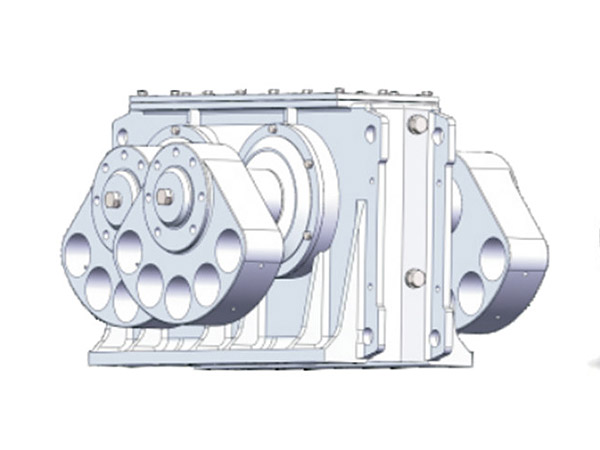

Linear vibrating screen structure and functional description of each part, linear vibrating screen is mainly composed of screen box, screen frame, screen mesh, vibrating motor, motor base, vibration damping spring, bracket, etc. The following vibrating screen manufacturers will introduce each linear vibrating screen in detail Parts composition, installation, use and maintenance work.

Structural composition of linear vibrating screen

1. Screen box: It is welded by several steel plates of different thicknesses. It has certain strength and rigidity and is the main part of the screening machine.

2. Screen frame: made of pine or wood with small deformation, it is mainly used to keep the screen flat and achieve normal screening.

3. Screen: There are several kinds of screens such as low carbon steel, brass, bronze, stainless steel wire.

4. Vibration motor (please refer to the vibration motor operation manual for operation and maintenance methods).

5. Motor base: install the vibration motor. Before use, the connecting screw must be tightened, especially three days before the trial of the new mesh screen machine, it must be tightened repeatedly to avoid accidents caused by loosening.

6. Damping spring: prevent vibration from being transmitted to the ground and support the overall weight of the screen box. When installed, the spring must be perpendicular to the ground.

7. Support: It consists of four columns and two channel steels to support the screen box. When installing, the columns must be perpendicular to the ground, and the channels under the two columns should be parallel to each other.

Preparations for installing linear vibrating screen

1. Check whether the motor logo meets the requirements.

2. Measure the insulation resistance with a 500-volt megger, and dry the stator winding at a temperature not exceeding 120.

3. Check the motor fasteners and beware of loosening.

4. Check whether the motor surface is damaged or deformed.

5. Check whether the rotation is flexible. If there is any abnormality, it should be excluded.

6. Check whether the power supply is out of phase, and run for 5 minutes with no load.

Installation and adjustment of linear vibrating screen

1. The motor should be fastened on the installation surface, and the installation surface must be smooth and flat.

2. The motor can be installed horizontally.

3. The motor lead adopts four-core rubber cable YZ-500V. When connecting the power supply, the lead wire is not allowed to bend sharply, and it must be securely fixed with the vibrating body.

4. The motor should have reliable grounding, the motor should have a grounding device, the lead terminals should be marked, and grounded with anchor bolts.

5. Adjustment of exciting force.

The use and maintenance of linear vibrating screen

1. This machine should be equipped with electrical protection devices.

2. During the initial operation of the machine, check the anchor bolts at least once a day to prevent loosening.

3. When the rotation direction of the motor does not meet the requirements, adjust the phase sequence of the power supply.

4. The motor should be well lubricated, and the lithium-based grease (ZL-3) should be replenished every two weeks or so. When refueling, an appropriate amount of lithium-based grease should be added through the oil cup. When using sealed bearings, the motor is not equipped with an oil cup.

5. After the machine has been running for 1500 hours, check the bearing and replace it immediately if it is seriously damaged.

6. When the machine is stopped for a long time and used again, the insulation resistance should be measured. For the measurement of a 500-volt megger, the insulation resistance should be greater than 0.5 megohm.

Daily maintenance of linear vibrating screen

1. Before starting: (1) Check whether the coarse net and fine net are damaged; (2) Check whether the transport bracket is removed.

2. When starting: (1) Pay attention to whether there is abnormal noise (2) Whether the current is stable (3) Whether the vibration is abnormal.

3. After use: Clean up after each use. Regular maintenance. Check whether the coarse mesh, fine mesh and spring are damaged by fatigue, and whether various parts of the fuselage are damaged by vibration. Parts that need to be lubricated must be lubricated with oil.

Installation, commissioning and trial operation of linear vibrating screen

1. Installation: Before installing the machine, first check whether the parts are complete and damaged according to the packing list; the equipment should be installed according to the installation drawing, and the foundation should have sufficient rigidity and strength to support all dynamic and static loads.

2. Adjustment and trial operation: the spring must be in a vertical state, and the contact surface between the upper spring bracket and the spring must be in a horizontal state. After adjustment, fix the upper spring bracket on the trunnion of the screen box with bolts, and then weld into one; the no-load test run time shall not be less than 2 hours. After the no-load trial operation is qualified, it can be put into the load trial operation, and the load trial operation can be carried out according to the technical trial operation requirements.

The above is a detailed introduction to the installation and debugging of the vibrating screen. The linear vibrating screen has high screening accuracy, large processing capacity, simple structure, low energy consumption, low noise, long service life of the screen, good sealing, very little dust spillage, Features such as convenient maintenance are widely used in automated operations in assembly line production. If you have any questions during use, look forward to your letter of consultation.