Emkhakheni wokulungiswa kwemishini yezimboni, njengenye yezinto ezisetshenziswayo ezibalulekile, i-exciter yesikrini esidlidlizayo kufanele ilandele uchungechunge lwezinyathelo namazinga phakathi nenqubo yokuyilungisa ukuze kuqinisekiswe ukwethembeka nokuqina kwaso. Inqubo yokugcinwa kwe-exciter yesikrini esidlidlizayo ihlanganisa uchungechunge lwemisebenzi eqinile, kusukela ekuthatheni izithombe nasekugcineni kungobo yomlando isimo sangempela somshini ngemva kokungena embonini, kuya kunqubo ebanzi yokudweba nokuthumela. Isinyathelo ngasinye sithinta kakhulu ikhwalithi yemiphumela yokulungisa. Ukuze kuqinisekiswe ikhwalithi yokunakekelwa, izidingo ezihlukahlukene ekulungiseni i-exciter yesikrini esidlidlizayo nazo zibaluleke kakhulu. Kusukela kumabhere kuya emabhokisini, kuye kumagiya nezinye izingxenye, izindinganiso ezifanele kanye nokucaciswa kwazo kufanele kulandelwe ngokuqinile ukuze kuqinisekiswe ukuthi i-exciter yesikrini esidlidlizayo iyagcinwa ngesikhathi sokulungiswa. Ekugcineni, ukusebenza okulindelekile kungafinyelelwa.

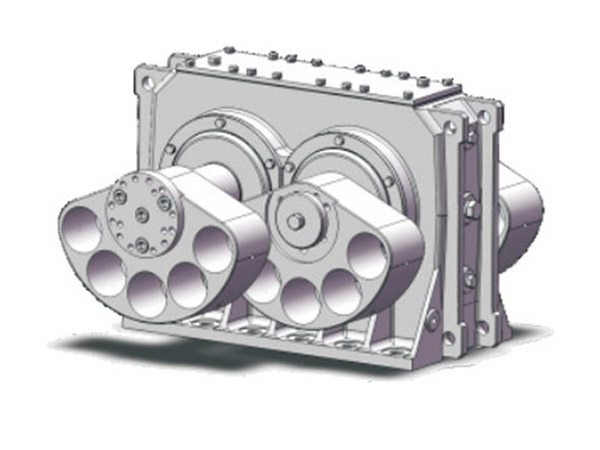

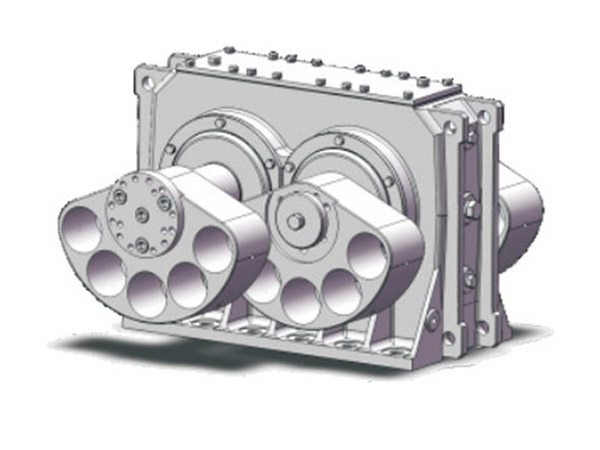

Ukulungiswa kwe-exciter yesikrini esidlidlizayo

1. Inqubo yokulungisa isidlidlizi

Thatha izithombe bese ugcina kungobo yomlando isimo sangempela somshini ngemva kokungena efekthri → Ukuqhuma kwesibhamu → I-primer ye-spray → Hlukanisa isidlidlizi → Thatha izithombe bese ufaka kungobo yomlando izingxenye → Hlanza izingxenye → Hlola, hlola futhi ubeke kungobo yomlando → Khipha umbiko wokuhlola → Umthengisi uzokhipha qinisekisa umonakalo ngomsebenzisi Yakha ifomu lokuqinisekisa ukunqunywa komonakalo → yenza uhlelo lokulungisa → thola izingxenye → hlola, rekhoda futhi ubeke kungobo yomlando → ukuhlanzwa nge-ultrasonic → ukuhlanganisa → ukuhlola nokuqopha kanye nefayela → fafaza ngopende → umkhumbi

2. Izidingo zokugcinwa kwe-Vibrator

Kufanele ishintshwe ngesikhathi sokulungiswa, futhi ama-bearings akhethekile e-SKF ekhwalithi ephezulu yezikrini ezidlidlizayo kufanele akhethwe ukuze kuqinisekiswe ukuthi angakwazi ukumelana nezimo zokusebenza zokudlidliza okunamandla futhi alondoloze ukusebenza okuzinzile kwesikhathi eside. Umsebenzi wokufaka nokulungisa ngokucophelela nawo ubalulekile ukuze kuqinisekiswe indawo yokufaka efanele kanye nesimo esivamile sokusebenza sama-bearings.

Ukushintshwa kwezimpawu kuyisiqinisekiso esibalulekile sokusebenza okuvamile kwe-exciter. Uma ushintsha, kuyadingeka ukukhetha izimpawu zekhwalithi eziphezulu ezihambisana nezingxenye zangempela ukuze kuqinisekiswe ukuthi zingakwazi ukuvimbela ngokuphumelelayo ukuvuza kwamafutha okugcoba noma ezinye izinto, ngaleyo ndlela zivikele izingxenye zangaphakathi ze-exciter emonakalweni.

Amabhokisi aqhekekile, akhubazekile, alimele noma agugile kufanele ashintshwe; lapho imbobo yebhokisi kanye nendawo yokufaka iringi yangaphandle ethwalayo kugqokwa futhi ukuthwala kungahlangabezani nezidingo zomhlangano, kufanele kushintshwe. Ibhokisi elisha kufanele lithathelwe indawo yensimbi ephezulu ye-ductile iron QT400-12, engenazo iziphambeko ezifana ne-slag inclusions, ama-pores, imifantu, njll futhi ihlolwe yi-ultrasonic ukuqinisekisa ukuqina nokuzinza kwayo. Ngesikhathi sokucutshungulwa kwekhabhinethi, inqubo yokunemba yemishini yesikhungo semishini ye-CNC kufanele isetshenziswe ngokuqinile ukuze kuqinisekiswe ukunemba nokuzinza kwekhabhinethi.

Phakathi nenqubo yokulungisa, ukushintshwa kwe-shaft kuyisixhumanisi esibalulekile sokuqinisekisa ukusebenza okuvamile kwesidlidlizi. Uma kunamamaki asobala we-concave kanye ne-convex ebusweni be-shaft, i-ovality yendawo yokuthwala kanye nesikhundla segiya ngu-≥0.01mm, futhi ubukhulu bomhlangano we-shaft neringi yangaphakathi ye-bearing abuhlangabezani nezidingo. kufanele kushintshwe. I-shaft esikhundleni senziwe nge-alloy structural steel 42CrMo ecutshungulwa ngamathuluzi omshini we-CNC, angaqinisekisa amandla amahle nokumelana nokugqoka. Ngesikhathi senqubo yokufaka, qinisekisa ukuthi ubukhulu bokuhlanganiswa kwe-shaft neringi yangaphakathi yebheringi kuhlangabezana nezidingo zokuqinisekisa ukusebenza kwesidlidlizi.

Ngesikhathi sokulungiswa, ukushintshwa kwegiya kuyisihluthulelo sokuqinisekisa ukusebenza okuvamile kwesistimu yokudlulisela. Amagiya kufanele ashintshwe lapho kugobhoza amazinyo namazinyo aphukile, ukuguga okungaphezulu, izindawo ezingaphezulu eziwayo, ukuwohloka kwezilwanyana ezinwabuzelayo, njll., futhi ukunemba kwegiya elishintshayo kufanele kube ileveli 5, futhi imvume yokungena kwegiya kufanele ibe ≤0.24mm. Phakathi nenqubo yokushintshanisa, ukucaciswa kwe-meshing kwamagiya kufanele kulawulwe ngaphakathi kwebanga elifanele ukuze kuqinisekiswe ukusebenza okuvamile nokusebenza kahle kwesistimu yokudlulisa.

Hlola izingxenye ngokwemidwebo, futhi lezo ezingabekezeleleki kufanele zishintshwe. Izingxenye ezishintshayo ziyimikhiqizo eyenziwe ekhaya ukuze kuqinisekiswe ukusebenza okuzinzile nokuthembeka kwesikhathi eside kohlelo lonke.

- Izingxenye ezijwayelekile

Zonke izingxenye ezijwayelekile kufanele zishintshwe kufakwe amabhawodi anguthayela ebanga lesi-8.8 ukuze kuqinisekiswe ukuxhumana okuzinzile nokuthembekile kwezingxenye ezihlukahlukene ze-exciter futhi kugwenywe izingozi ezingase zibe khona zokuphepha kanye nokwehluleka kwemishini okubangelwa ukuxega noma ukuwa.

Ngemuva kokuthi i-exciter isilungisiwe, ukuhlolwa okuqinile kufanele kwenziwe. Isikhathi sokuhlola singu-≥36h, izinga lokushisa lokusebenza likhuphuka ngu-≤60℃, umsindo uthi ≤85db (A), futhi awukho umsindo ongajwayelekile noma ukuvuza kukawoyela, kuthathwa njengokufanelekile.

- Futha imininingwane yokudweba

Phakathi nenqubo yokudweba, ikhodi yombala kufanele iqinisekiswe futhi ipendwe ngokusekelwe kumbala womshini wokuqala. Ubukhulu befilimu kapende kufanele bube ngu-≥0.3mm. Ikakhulukazi uma ingaphakathi lekhabhinethi lidinga ukulungiswa ngenxa yokulimala kwefilimu ephikisana nopende, umsebenzi wokulungisa kufanele wenziwe ngokucophelela ukuze kuqinisekiswe ukuqina kwawo kanye nobuqotho bezimonyo.

3. Izinyathelo zokuqapha ngokulungiswa kwe-vibrator

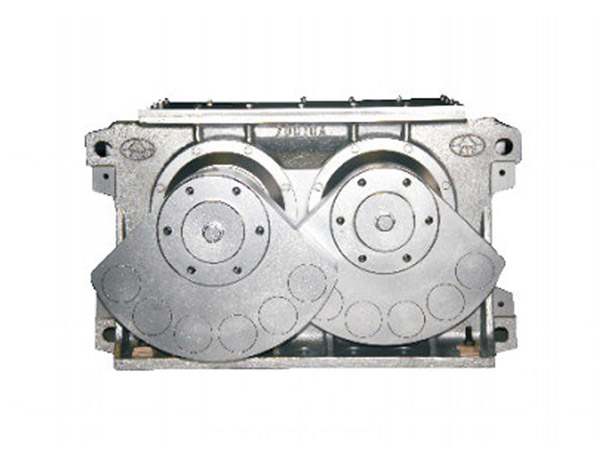

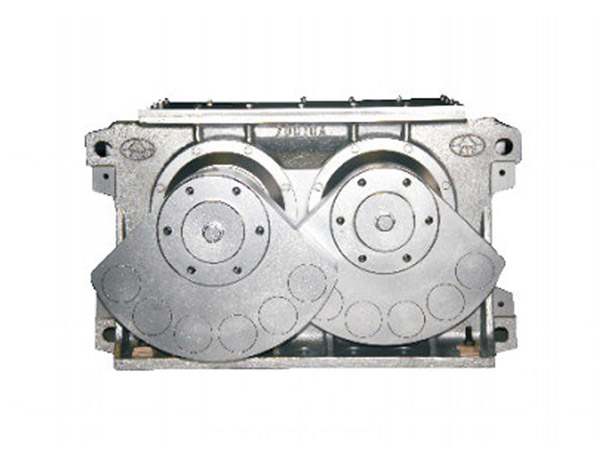

1. Ibhokisi

Bheka ibhokisi ngokuqhekeka, ukuwohloka, ukulimala kwentambo, ukuguga nokunye ukonakala. Uma ibhokisi lingenazo iziphambeko ezisobala, amathuluzi akhethekile njengesibonisi sokudayela esiphakathi nendawo kanye ne-micrometer izosetshenziswa ukuze kuhlolwe ubukhulu obuhlukahlukene bebhokisi. Amabhokisi adlula ukuhlolwa azohlelwa ukuze kutholwe amaphutha e-ultrasonic. Ibhokisi lingasetshenziswa kuphela ngemuva kokuthola iphutha. Kumabhokisi anokungabaza okufana nokuwohloka okunzima ukuwaqinisekisa, sebenzisa izixhumanisi ezinezinhlangothi ezintathu ukuze uhlole futhi unqume ukuhlangana kwebhokisi. Amabhokisi afanelekayo kuphela angasetshenziswa.

2. Amagiya

Okokuqala bheka ukuthi akhona yini amazinyo abhodlokile namazinyo aphukile, ukuguga ngokweqile, izindawo eziwayo eziwayo, ukuwohloka kwe-surface creep, njll.; uma zingekho izinkinga, sebenzisa amathuluzi akhethekile njengezinkomba zokudayela ububanzi obungaphakathi nama-micrometer ukuhlola ubukhulu bamagiya; amagiya adlula ukuhlolwa kwe-dimensional azohlolwa izinhlayiya kazibuthe. + Ukutholwa kwamaphutha e-Ultrasonic; amagiya kuphela adlula ukutholwa kwamaphutha angasetshenziswa. Mayelana namalungiselelo egiya anokukhubazeka okungabazekayo okunzima ukukuqinisekisa, sebenzisa umtshina wegiya ukuze ubuyekeze futhi unqume ukuma kwamazinyo, futhi amagiya afanelekayo kuphela angasetshenziswa.

3. I-eksisi

Okokuqala bheka ukungalingani okusobala futhi ugqoke amamaki ebusweni bomgodi; uma zingekho izinkinga, sebenzisa amathuluzi akhethekile njengama-micrometer ukuze uhlole ubukhulu be-shaft; ngemva kokudlula ukuhlolwa, qhuba inhlayiya kazibuthe + ukutholwa kwamaphutha e-ultrasonic ku-shaft; ingasetshenziswa kuphela ngemva kokudlulisa ukutholwa kwephutha. Ezingxenyeni ze-shaft okunzima ukunquma ukuguquguquka kwe-deformation kanye ne-coaxiality, hlela isheke lokuxhumanisa le-three-dimensional ukuze uhlole i-coaxiality ye-shaft, futhi lezo zingxenye kuphela ezidlula izinga zingasetshenziswa.

4. Umhlangano

Qinisekisa ukuthi indawo yomhlangano ihlanzekile, futhi ukuhlanzwa kwe-ultrasonic kuyadingeka ngaphambi kokuhlanganiswa ukuze kuqinisekiswe ukuthi zonke izingxenye zihlanzekile futhi azinawo amabala; hlola amathuluzi okuhlanganisa nawokufaka acindezelwe ashiwo futhi uwalungise uma kunesidingo; hlanganisa futhi uhlole ngokuya ngemininingwane yenqubo; hlela izidlidlizi eziqeqeshiwe Yenza izivivinyo ukuze uqinisekise ukuthobelana “Nezicaciso Zokuhlola Isidlidlizi”.

Ngesikhathi sokunakekelwa kwesidlidlizi, ngaphezu kokulandela ngokuqinile izinqubo zokunakekela isidlidlizi, kubalulekile futhi ukubheka izinyathelo zokuphepha. Ikakhulukazi ekuqapheni nasekuhlolweni kwamabhokisi, amagiya, ama-shafts nezinqubo zokuhlanganisa, kufanele kuthathwe izinyathelo ezinembe kanye nemininingwane eminingi. Lokhu akuhlanganisi kuphela ukuqinisekiswa kobukhulu obuhlukahlukene, kodwa futhi kudinga ukusetshenziswa kwamathuluzi okuhlola nobuchwepheshe, obufana nezinhlayiya kazibuthe + ukutholwa kwamaphutha e-ultrasonic kanye nezixhumanisi ezinezinhlangothi ezintathu, ukuze kuqinisekiswe ukuthi i-exciter elungisiwe ingahambisana nezicaciso ezifanele kanye namazinga. Kuphela ngokulandela ngokuqinile lezi zinyathelo zokuphepha zokunakekela eziqinile lapho ukuthembeka nokuzinza kwekhwalithi yokugcinwa kwesidlidlizi kungaqinisekiswa, ngaleyo ndlela kuqinisekiswe ukusebenza kwaso okuphumelelayo nokuzinzile ekukhiqizeni kwezimboni.