ARC VIBRATING SCREEN

There are two types of arc vibrating screens: fixed type and vibrating type. The installation method can be divided into hanging type and seat type. The screen body can be turned over to extend the service life of the screen plate. The tilt angle of the equipment can be adjusted appropriately according to the site conditions. The vibration motor excitation force of the vibrating arc screen can be adjusted within a certain range to meet the dehydration effect.

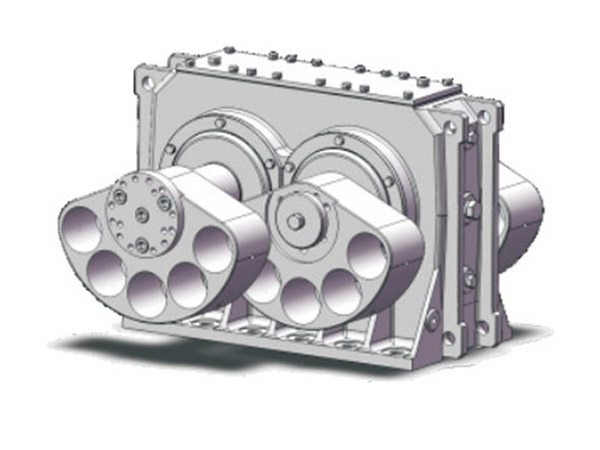

The arc vibrating screen is generally installed before the power screen to reduce the area of the power screen. It has a simple structure, small floor space, good dehydration effect, easy maintenance, and material is not easy to block; the screen machine has a wrap angle of 45 degrees and 60 degrees; The curvature radius is 2030mm and the screen box is composed; the arc screen surface and the screen frame adopt the pivot-specific structure, which can rotate 180 degrees to extend the service life of the screen surface.

Working principle of arc vibrating screen

The dewatering principle of the arc vibrating screen is to rely on the cutting effect of the sharp edges on the inlet side of the screen bar to separate the slime water; according to the use occasion and the disparity of the material moisture, the arc vibrating screen is divided into vibrating and fixed arc vibrating screen. The arc-shaped vibrating screen is turned over by the feed box, the screen box and the sieve base shaft, which realizes the position of the feed end and the discharge end, achieves uniform wear, prolongs the service life and is flexible and convenient.