BANANA VIBRATING SCREEN

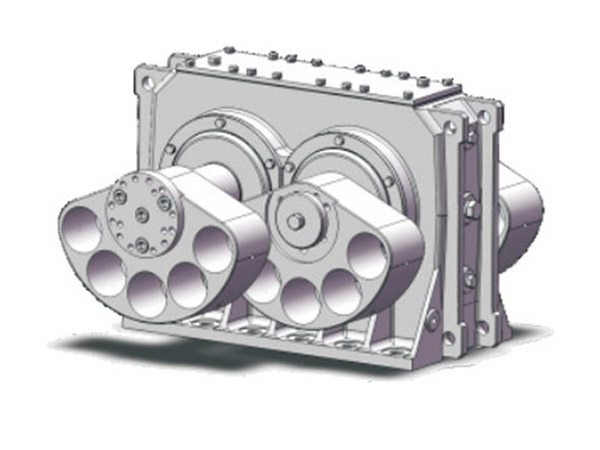

The banana vibrating screen is a self-synchronizing heavy-duty equal-thickness screen. The screen box is similar to the shape of a banana. The screen beam adopts a box-shaped beam. The vibrator and the exciter are connected by an intermediate transmission shaft.

Banana vibrating screen is widely used in coal grading, desliming, dewatering, de-intermediation, and can also be used for screening in large-volume mining operations in mines. Compared with the traditional sieve of the same specification, the banana vibrating screen developed by our company has a larger processing capacity. Its processing capacity per unit area is 1.5~2 times that of the traditional one. It is a kind of vibrating screen with higher cost performance.

Advantages of banana vibrating screen

- Simple and compact structure, high rigidity, high strength, balanced force distribution, and large safety factor;

- The vibration parameters are set reasonably to avoid the natural frequencies of the screen body at all levels and reduce the impact of resonance;

- The service life of the screen body is up to 10 years, and the service life of the vibrating screen exciter is more than 60,000 hours;

- Light weight, low power consumption, high vibration intensity (9-12mm), high screening efficiency (> 95%);

- Select brand patented screen surface configuration, high screening efficiency and large material handling capacity;

- The working noise level is less than 75 decibels, and the operation is stable;

- The working system of the whole machine is S1, which guarantees stable and continuous work for 24 hours;

- The banana vibrating screen adopts imported FF professional frequency analyzer for frequency response and dynamic analysis;

- The variety is complete, which can fully meet the screening process requirements of different material characteristics and throughput;

- The banana vibrating screen is simple to operate and maintain, safe to use, cost-effective, sufficient spare parts, and timely and thoughtful service.